설명

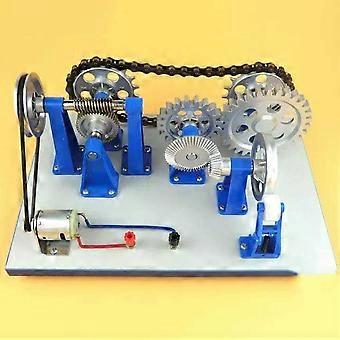

Mechanical Transmission Model with Six Transmission Types for Classroom Physics Experiment Training Kit

Compact mechanical transmission model for observation and experiment

Product overview

A compact, motordriven mechanical transmission model that demonstrates six common transmission types in sequence. The unit measures 305 x 200 x 140 mm, weighs 2 kg, and is built for classroom demonstration, lab experiments, and handson training. The model is driven by a DC motor and requires a usersupplied DC power supply.

Key specifications

Overall size: 305 x 200 x 140 mm

Model starting voltage: 4.5 to 8 V DC

Weight: 2 kg

Base material: solid wood board

Gear material: engineering plastic

Chain material: metal

Main component sizes

Belt drive pulleys: large pulley diameter 60 x 10 mm, small pulley diameter 14 x 10 mm

Chain drive sprocket: diameter 80 x 8 mm

Cylindrical gear set: large gear diameter 95 x 10 mm, 30 teeth; pinion diameter 65 x 10 mm, 20 teeth

Turbine worm set: turbine diameter 50 x 8 mm, 50 teeth; worm heads 25

Friction wheels: large friction wheel diameter 64 x 10 mm, small friction wheel diameter 23 x 12 mm

Included transmission types

Belt drive

Turbine worm drive

Chain drive

Cylindrical gear drive

Bevel gear drive

Friction wheel drive

How it works

The DC motor provides the initial drive. Drive sequence:

1. Motor drives the first shaft and belt drive.

2. The beltdriven shaft turns the turbine via a vortex rod to create the turbine worm drive.

3. After two stages of deceleration, the turbine shaft engages the chain drive.

4. The chain stage drives the subsequent cylindrical gear stage, then the bevel gear stage, and finally the friction wheel stage.

This staged layout makes changes in speed and torque visible and easy to study.

Why this model is useful

Clear demonstration of transmission principles: sequential stages allow observation of speed reduction, torque increase, and direction changes across different transmission types.

Solid, serviceable construction: a wooden base for stability, engineering plastic gears for clear tooth geometry, and a metal chain for realistic load transfer.

Compact and portable: tabletop footprint and 2 kg weight make it suitable for classroom benches and lab tables.

Easy to power and observe: compatible with common DC power supplies within the 4.5 to 8 V starting range.

Operation and setup

Place the instrument horizontally on a flat table.

Insert the adapter plug into the instrument power socket.

Connect the adapter to the DC output of a usersupplied DC power supply.

Start with low voltage within the 4.5 to 8 V starting range and adjust as needed for safe observation.

Practical applications and use scenarios

Classroom demonstration: Show students how belt, worm, chain, spur, bevel, and friction transmissions differ in speed ratio, torque, and direction change during a lecture or lab session.

Vocational and technical training: Use the model for handson training in mechanical systems, maintenance, and troubleshooting of common transmission types.

Prototype testing and hobby projects: Validate gear ratios and mechanical interactions when designing small machines or educational models.

What to expect

A compact, durable demonstration unit that provides visible, stepbystep transmission of motion from motor to final output.

Clear physical examples of pulleys, sprockets, gears, worms, and friction wheels with labeled component sizes for reference and calculation.

Requirement: a compatible DC power supply must be provided by the user.

-

Fruugo ID:

462979222-974206415

-

EAN:

6091977326983